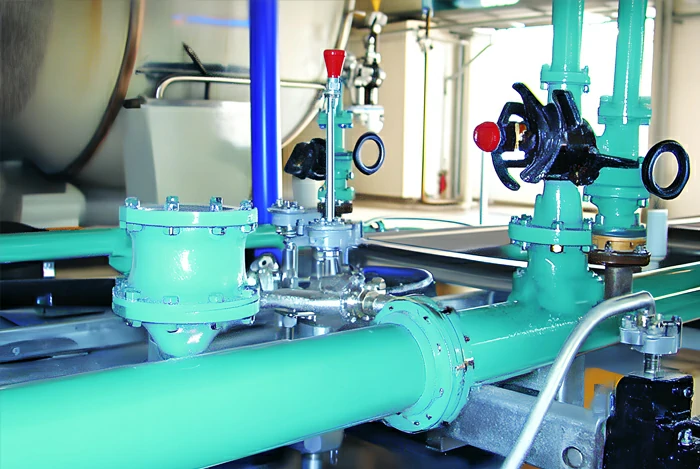

We specialize in providing high-quality components for the fluid control and process industry. Our investment casting, precision machining, and welding services ensure the reliability, precision, and durability required for fluid handling systems and process equipment.

Therefore, we focus on delivering high-precision components that are meticulously designed and manufactured to meet the specific needs of our clients. Our products are rigorously tested to ensure they perform flawlessly in a variety of operating conditions, providing our customers with the peace of mind that their systems will run smoothly and efficiently.

Capable of producing fluid control components with complex geometries and tight tolerances. Advanced CNC technology ensures dimensional accuracy and surface finish.

Supports materials such as stainless steel, brass, and titanium alloy, ideal for fluid control applications.

Smooth casting surfaces and optimized machining processes reduce the need for post-processing and shorten delivery times.

Offers end-to-end solutions from design to production, supporting both small and large batches. Capable of handling intricate fluid control component designs.

Advanced welding techniques ensure robust and reliable joints for pipelines and process equipment.

Provides high-value solutions while adhering to industry standards and rigorous quality control processes.

We are committed to providing customers with one-stop solutions for investment casting, precision machining, and welding services in the fluid control and process industry. With advanced technology, strict quality control, and extensive industry experience, we ensure every project meets customer expectations.