Investment casting, also known as "lost wax casting" or "precision casting," is a distinguished metal-forming technique. In this process, wax patterns are meticulously crafted and subsequently encased in ceramic materials to form molds. Once the ceramic shell has fully hardened, the wax is melted and evacuated, leaving behind a precisely shaped cavity.

Molten metal is then poured into this cavity and allowed to solidify. After cooling, the final castings are obtained. This method enables the production of components with exceptional precision and intricate details, making it ideal for complex designs while significantly reducing the need for post-production machining.

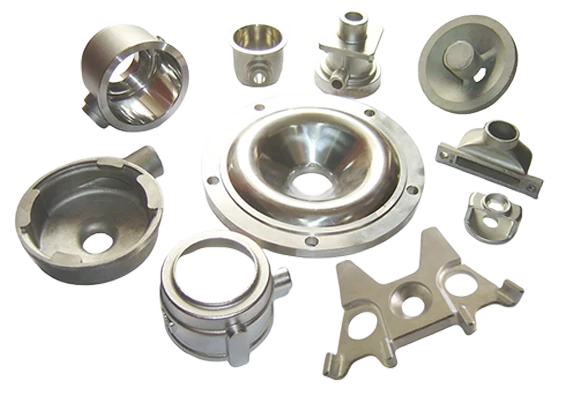

Our company has a rich variety of casting technologies, including the silica sol process, the sodium silicate process, and the composite process. These technologies enable us to meet the diverse needs of different customers for various types of castings.

Our company has outstanding surface treatment capabilities and can provide diverse surface treatment solutions based on the specific requirements of customers and the structural characteristics of parts.

The company aims to provide top-quality Chinese products at competitive prices. We focus on functionality first, then develop the product, ensuring good design through material choice.

Quality control involves strict raw material screening, precise process control in production, multiple whole process inspections, and a traceability system setup to ensure high standard casting dimensions, surface, internal structure, and performance.

Our investment casting expertise meets diverse industry needs with high-quality components. We collaborate with clients to develop cost-effective, optimal solutions ensuring efficient production.