Using silica sol as the binder, its process is similar to that of sodium silicate investment casting, but silica sol has better bonding properties and high-temperature stability. During the coating process, the silica sol can combine better with the refractory materials, making the mold shell have higher strength and precision. After the mold shell is fabricated, it also goes through processes such as dewaxing and roasting, and then casting is carried out.

It is suitable for the production of castings with high precision, high surface quality requirements, and complex shapes, such as components in the aerospace, medical device, and precision instrument industries.

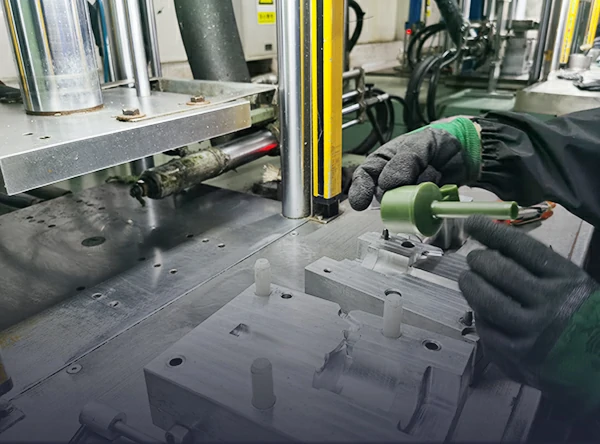

Starting from the creation of a delicate wax pattern, it unfolds a meticulous journey through multiple steps, ultimately delivering high - quality, intricately - designed castings for diverse industries.

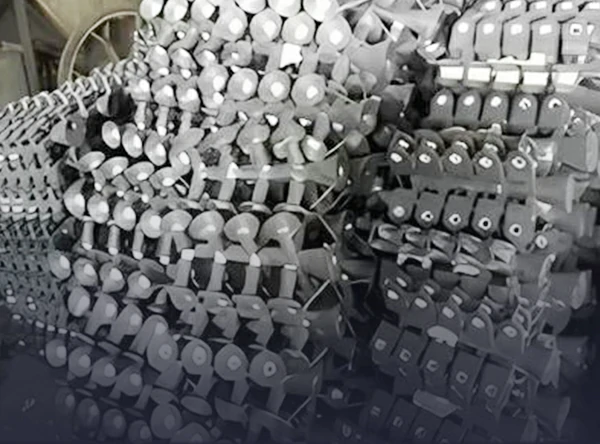

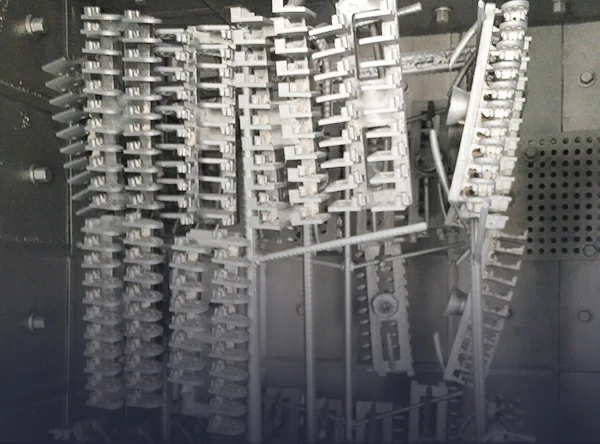

Using sodium silicate as the binder, multiple layers of refractory materials are coated on the surface of the wax pattern. First, immerse the wax pattern in the sodium silicate solution, and then sprinkle quartz sand. Repeat the coating and sand sprinkling operations several times to form a mold shell with a certain thickness. After the mold shell is dried and hardened, heat it to melt away the wax pattern to obtain a hollow mold shell. Then, carry out roasting. Finally, pour the liquid metal into the mold shell, and the casting is obtained after cooling and solidification.

It is widely used in the production of small and medium-sized castings with general precision requirements and moderate complexity, such as mechanical parts and hardware tools, and is more commonly applied in some industries that are sensitive to costs.

Combining the advantages of sodium silicate and silica sol, usually sodium silicate is used as the inner layer binder and silica sol is used as the outer layer binder to make the mold shell. First, coat multiple layers of sodium silicate on the wax pattern to form the inner layer mold shell, and then coat the outer layer with silica sol. In this way, while ensuring the strength of the mold shell, the surface quality and dimensional accuracy of the mold shell can be improved. Subsequent processes such as dewaxing, roasting, and casting are the same as those of other investment casting processes.

It is suitable for occasions with high requirements for the precision and surface quality of castings, while also requiring cost control. It can be used to produce some castings with larger sizes or more complex structures, such as automotive components, pumps, and valves.