Base on industry norms and customer needs, create detailed, strict quality standards covering casting dimensional accuracy, surface quality, etc.

Set up a full - process quality control from raw material purchase to product delivery. Define quality control points and operation specs for each step. For example, specify shell making layers, drying time/temperature in shell making.

Create a dedicated quality management dept with pros. Clarify each dept's and person's role in quality control to ensure effective work.

Rigorously inspect investment casting raw materials (wax, shell, metal charge). Check chem comp, physical props to meet process needs and ensure casting quality at the start.

Wax Pattern Making: Control wax pattern mfg for accurate size and good surface. Strictly manage press temp, pressure, hold time. Regularly check wax pattern size and appearance.

Shell Making: Precisely control shell prep (coating, layer num, drying) to avoid shell cracks and delamination.

Smelting & Pouring: Control molten metal smelting for right chem comp and temp. During pouring, manage speed, temp, filling time to prevent short shots and cold shuts.

Heat Treatment: Make suitable heat treatment process based on casting material and performance. Control heating, holding, cooling to get good casting structure and props.

Equipment Maintenance: Regularly service investment casting equipment. Calibrate and test key gear like smelting furnaces and die casters for accuracy and stability.

During production, intensify inspection of each process (wax pattern, shell, post - pour casting) to catch and fix quality issues, stopping bad products from moving forward.

Set up a system to record each casting's production details (raw mat batch, equip, time, operator, inspection). This helps quickly trace quality problem sources, take corrective actions, and prevent repeats.

Wax Pattern Making: Control wax pattern mfg for accurate size and good surface. Strictly manage press temp, pressure, hold time. Regularly check wax pattern size and appearance.

Appearance Inspection: Thoroughly check casting appearance (roughness, pores, burrs) with visual and optical methods.

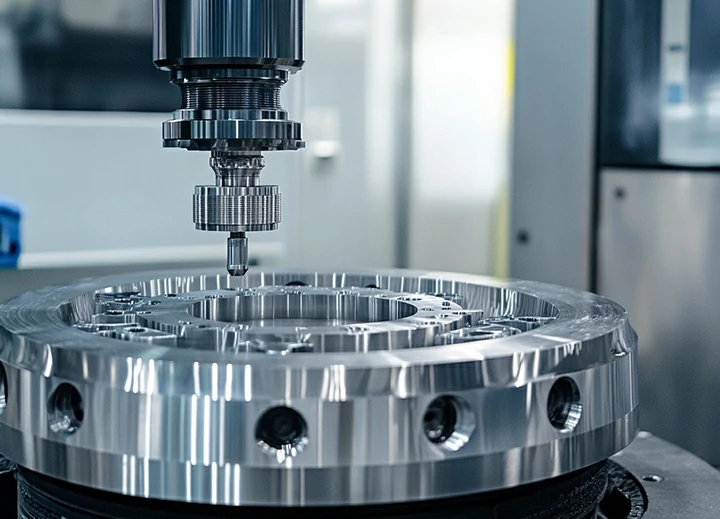

Dimensional Accuracy Measurement: Use calipers, micrometers, CMMs to measure key casting dimensions within design required range.

Internal Quality Detection: Employ non - destructive tests (radiographic, ultrasonic, magnetic particle) for internal defects. For high end castings, do metallographic and mechanical property tests.