In the field of material processing, our company, with its rich experience and advanced technology, is capable of efficiently handling various types of raw materials. The commonly processed raw materials mainly include castings, bars, and profiles.

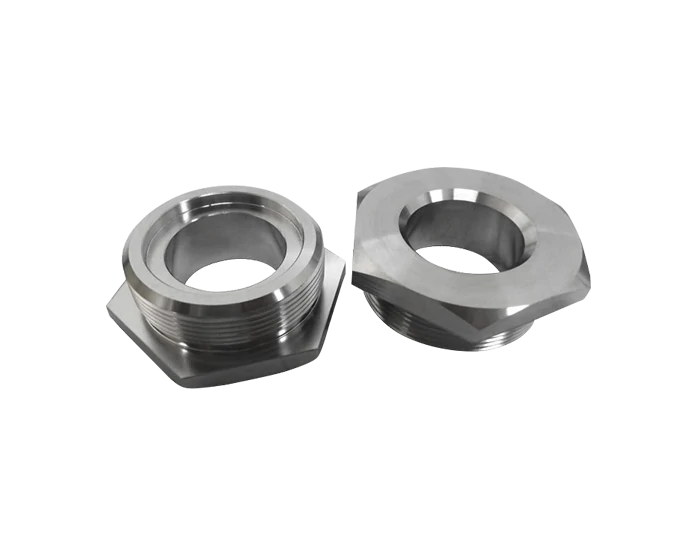

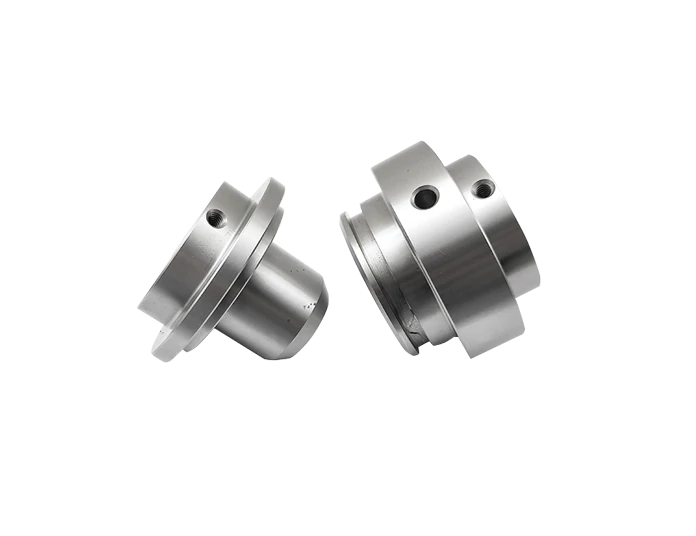

As for castings, we can process a variety of materials such as cast steel, cast aluminum, and cast copper. Cast steel, due to its high strength and good toughness, is often used in the manufacturing of key components that bear heavy loads, such as crane booms and large gears. Cast aluminum, with its characteristics of low density, high specific strength, and strong corrosion resistance, is widely applied in engine components in the aerospace field and in the lightweight design of the automotive industry. Cast copper, relying on its excellent electrical conductivity, thermal conductivity, and corrosion resistance, performs outstandingly in the manufacturing of parts such as connectors and valves for electrical equipment.

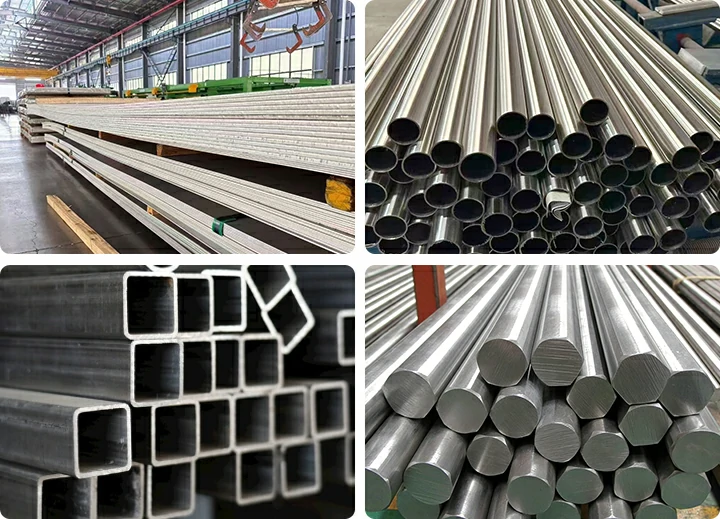

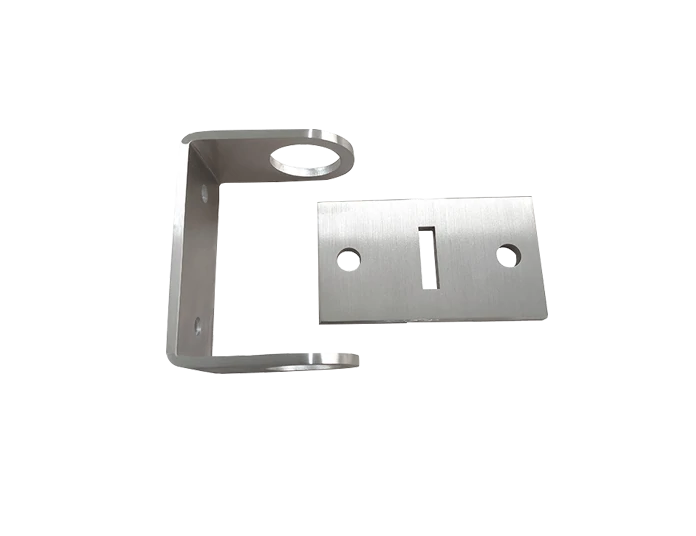

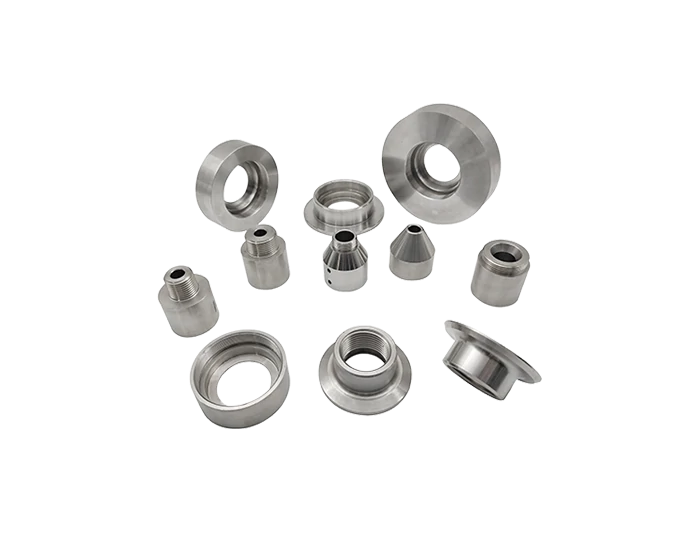

We also possess profound professional capabilities in the processing of bars and profiles. For bars, we can process different materials such as round steel, hexagonal steel, and free-cutting steel, which can meet the diverse needs ranging from ordinary mechanical parts to high-precision industrial components. For example, round steel is often used to manufacture drive shafts, and hexagonal steel is an ideal raw material for standard nuts and bolts. In terms of profiles, whether it is angle steel, channel steel, I-beam commonly used in building structures, or aluminum profiles widely applied in modern industry and architectural decoration, we can carry out precise processing according to customers' requirements to ensure that the product quality reaches the leading level in the industry. From the selection of raw materials to the delivery of finished products, our company can provide you with one-stop, all-round high-quality services.