In addition to leaving the machined surface intact, there are various surface treatment methods for machined parts. The surface treatment methods of machined parts include electroplating, spraying, oxidation treatment, galvanizing, etc.

Through different principles and processes, these methods improve the surface properties of machined parts to meet their diverse requirements in aspects such as corrosion resistance, wear resistance, and decorativeness.

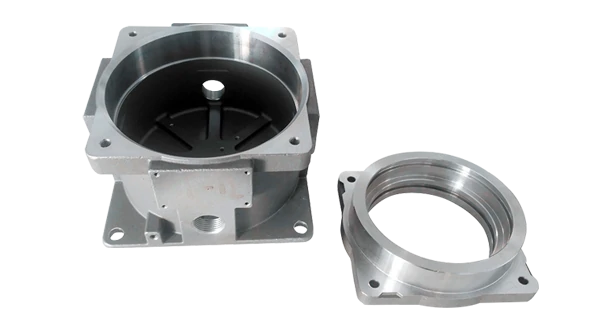

When the CNC machining process is completed, it can achieve a smooth surface finish with a minimum roughness of Ra6.3. In the absence of additional surface finish requirements, the parts will retain their as machined surfaces. Moreover, CNC machining is also capable of producing parts with higher surface finishes, such as Ra3.2 or Ra1.6.

This is the process of powder coating CNC machined parts and then baking them in an oven at a certain temperature. Compared with the painting process, the powder coating finish is more durable, because the surface layer of the CNC-machined parts is sturdy, wear-resistant and corrosion-resistant. A variety of colors can be chosen to achieve the decorative effect.

Anodizing is one of the most durable finishes that can prevent CNC-machined parts from being scratched. This type of surface finish is only applicable to machined aluminum parts. Similar to powder coating, a wide range of colors are available to create the desired appearance.

Galvanizing, also known as hot-dip galvanizing, is a process in which a thin layer of zinc is applied to the surface of CNC-machined steel parts through an electric current. After a protective layer of zinc oxide is formed, the CNC-machined parts will not rust when exposed to air or water.